Housing for Poultry

- The primary objective of providing housing to poultry is to protect them from sun, rain and predators and it is also essential to provide comfort.

- Poultry houses should be-well ventilated, reasonably cool in summer and warm during winter, and free from drafts.

- In hotter parts of the country, the long axis of the house should run from east to west and the sides should face north-south to prevent direct sunshine falling into the house. In colder parts of the country, it is desirable to construct the houses facing south or south-east to get maximum sunlight.

- The distance between two houses for birds of same age group should be at least 18 m to allow proper ventilation. But the young stock house should be at least 45 to 100 m away from the houses having adult stocks to prevent diseases.

- To avoid ventilation problem, the width of the house should not exceed 9 m in open-sided houses. The height of the house depends upon temperature of the place. Ordinarily the height of the house should be 2·4 to 3 m from the foundation to roof line. When height is more, it helps to reduce the inside temperature.

- A poultry house should not be expensive. But, durability, comfort and safety of house, however, should not be compromised.

- The floor of the house should be moisture-proof, free from cracks, easily cleaned, rat proof and durable. The different types of floor in use are all-litter floor, all-slate floor, slate and litter floor, wire and litter floor, and sloping wire floor.

- The walls and partitions must be solid enough to support the roof and withstand heavy winds. Wide variation is possible depending upon agro climatic conditions, availability and cost of construction materials.

- The roof must be draft and moisture proof. Insulation of roof helps both in summer as well as in winter. Where summer temperature is high, roof should be painted with a reflecting type of paint such as aluminum paint. An over-hang of 0·9 m will help to prevent the rain water splashing inside the house.

- The climatic conditions and age group of birds will determine the extent of side opening. Usually half to two-thirds area of the side walls are kept open in open-sided house fitted with wire mesh.

- In areas where temperature is high and continuous, more than two-thirds of the side wall area may be left open for proper ventilation.

- In brooder houses, half the area is left open, in grower and layer houses two-thirds and in cage houses the maximum. Irrespective of the house, all the Poultry houses should be located in well-drained grounds, safe from flood waters and with easy access from the road.

Location

The following are the desirable points to be borne in mind while selecting a location.

- Poultry house should be located away from residential and industrial area.

- Establish the farm preferably in an area where chicks and feed are easily available.

- Must have good source of electricity.

- There should be possibility of good drainage during monsoon.

- Drinking water must be readily and freely available.

- It should be near to the good market.

- It should have proper road facilities.

- Poultry house should be located in an elevated area and there should not be any water-logging.

Type of Poultry Housing Systems

1.Free Range System: It is oldest system and adopted only when adequate land is available. In this system of rearing, birds are reared by letting them loose on ground (field) called as range. A range should provide shelter, greens, feed, water, shade etc. Foraging is major source of feeding for birds. Shelter is usually provided by temporary roofing supported by ordinary poles. Stocking density is 300-400 birds per hectare and now days, it is adopted in organic system of poultry farming.

2. Semi-intensive System: Commonly used by small scale producers. Birds are half way reared in houses and half way on ground or range. Birds are confined to houses in night or as per the need, they are also given access to runs. Houses may be simple house, thatched roof, littered earth floor or slatted to provide protection from inclement. Stocking density is 4-5 birds per sq.m. in houses.

3. Intensive system of housing: It is a system where birds are kept in confined spaces, with no access to the outside. This system is often used when land is limited and is expensive. Intensive system of housing is further divided into following types. Deep litter system: Deep litter system is commonly used for broiler farming across the world. Floor is covered with bedding material, such as straw, saw dust or leaves up to depth of 2-3 inches. Birds are accessed for feed, water, egg collection, in closed housing system which provides good protection against adverse environmental condition. Bird density is one bird per square feet.

Points to be considered while adopting deep litter system

- The litter should always be kept dry.

- The birds should be housed as per the standard space requirement.

- The house should be well ventilated.

- The litter should be raked at least once in a week to keep litter dry otherwise wet litter may lead to litter born disease ( E. coli and salmonella infection)

- Placing of water should be given due attention to keep litter dry.

Advantages:

- It is an economical, hygienic, comfortable and safe system for birds

- Built up litter supplies vitamin B12 and Riboflavin to the birds

- Controls diseases and vices

- It increases the efficiency of production

- Materials such as paddy husks saw dust, dried leaf; chopped straw and groundnut kernels depending upon the availability can be used as litter materials.

Floor space, feeding space and watering space for chicks

| Age in weeks | Floor space Sq. ft./Chick | Feeding space inches/chick | Watering space inches/chick |

|---|---|---|---|

| 1 | 0-2 | 1.5 | 0.5 |

| 2 | 0.2 | 2.0 | 0.7 |

| 3 | 0.3 | 2.0 | 0.7 |

| 4 | 0.4 | 2.5 | 0.8 |

| 5 | 0.6 | 2.5 | 0.8 |

| 6 | 0.8 | 3.0 | 1.0 |

| 7 | 0.9 | 3.0 | 1.0 |

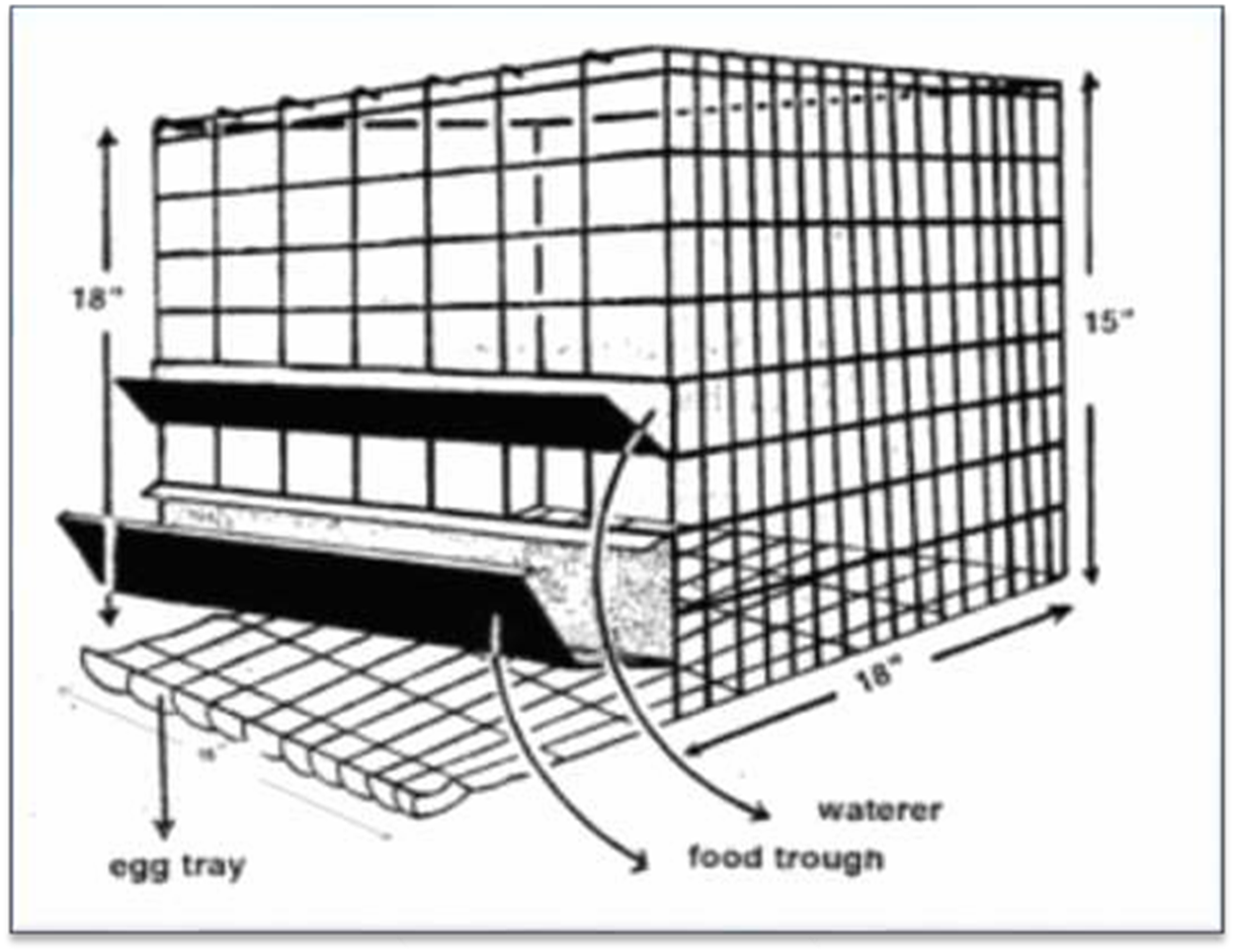

Cage system:The cage system of rearing birds has been considered as a super intensive system providing floor area of 450-525 sq.cm. (0.6-0.75 sq. Feet) per bird. In cage, the birds are kept in one, two or three per cage, arranged in single or double or triple rows.

Structure of Cage

Based on the bird density

- Single or individual bird cage (Only one bird in a cage)

- Multiple bird cage (From 2 to 10 birds)

- Colony cages (More than 11 birds per cage)

Based on the number of rows

- Single-deck

- Double-deck

- Triple-deck

- Four-deck

Based on arrangement of cages

- Battery cages (Vertical cages)

- Stair-step cages a) M-type cages b) L-type cages

Based on the type of bird reared

- Brooder / chick cages

- Grower cages

- Layer cages

- Breeder cages

California Housing (High Rise/ Elevated cage house)

- This type of houses provides sufficient ventilation and waste management in tropical countries

- The height of the shed is raised by 7-8 feet from ground level using concrete pillars

- The distance between two pillars is 10 feet

- Two feet wide concrete platforms are made over the pillars

- The inter-platform distance is 5-8 feet depending upon the type of the cages used

- The total height of the house is 20-25 feet and the width is 30-33 feet

Advantages

- Greater number of birds can be reared per unit of area

- Facilitates correct maintenance of records

- Helps in identifying poor producers and prompt culling

- Control of vices of poultry cannibalism and egg eating

- It helps in production of clean eggs

- Removal of stress factors

- Easy control of parasitic disease like coccidiosis and worm infestation

- Prompt steps to control feed wastage.

- The cage method of housing is ideal for the area of moderated climate conditions where the day temperature in summer does not high and temperature does not fall too low.

- Egg production of caged layer is reported to be more than those kept in deep litter system.

- Feed efficiency and egg weight is better in caged birds than the laying flock under deep litter system.

Disadvantages:

- Difficulties in ensuring proper ventilation to birds especially in summer season and under very high densed conditions.

- Incidence of leg problem, cage layer fatigue, fatty liver syndrome, flies and obnoxious gases in the house will be on increase.

- Cage fatigue: Cage fatigue is considered as physiological derangement of mineral electrolytes imbalance. Leg weakness is common in caged birds.

- Fatty live syndrome: It is a problem met with caged layers due to increased deposition of fat in the body resulting in death due to internal hemorrhage. Increasing the protein level and the diet strengthened by the addition of choline, vitamin B12, inositol and vitamin-E may be helpful in reducing the incidence of problem.

- Proper ventilation, correction of light-intensity, duration, temperature, ideal environmental conditions, and maintenance of comfort in cages will check the conditions of hysteria of chicken in cages.

Environmentally Controlled House (ECH):

Environmentally controlled house (ECH) is one in which inside conditions are maintained as near as to the bird’s optimum requirements. A closed building, longitudinal preferably east to west, with big exhaust fans on west side while evaporative cooling pads on east side along with automatic feeding and drinking systems inside, in order to maintain proper ventilation and temperature. In environmentally controlled poultry houses, the dimensions are usually 40-50 ft wide, 400- 600 ft long with 8 ft high sidewalls. Space required for broilers is 0.8 sq ft/ bird.

Importance of ECH:

- To regulate the ventilation inside the house.

- To minimize the temperature fluctuation in the house.

- To maintain proper relative humidity inside house.

- To maintain proper lighting inside house.

- To obtain better FCR in birds.

- To obtain uniform air movement.

- To lower the medication cost.

- To lower mortality in the birds.

Comparative Efficiency of Environment Control (ECH) and Conventional Open-Side House (COH):

The technology of ECH is rapidly becoming popular among broiler producers due to its following significant advantages:

- The ECH brings down the temperature by 10 to150C as compared to the conventional open-sided houses (COH) and makes it comfortable like colder regions.

- Due to severe heat stress during 4 long summer months the broiler production is stopped in COH, resultantly only 4-5 flocks are possible in such houses in a year. However, in ECH 8 batches of birds are marketed without any break.

- ECH being complete closed system has minimized the incidence of diseases, cutting down the cost of vaccine and medication i.e.Rs.2/bird against Rs.5/bird in COH.

- Mortality in ECH has been decreased to 2-3% as compared to 8-10% in COH.

- In ECH, a broiler flock is ready for market in 35 days as compared to 42 days in COH.

- Feed conversion ratio (FCR) of broiler in COH is 1.9 to 2, whereas this figure of FCR is improved to 1.7-1.8 in ECH. All these significant features in ECH can reduce the cost of production of broiler to Rs.35/Kg as compared to Rs.40/Kg in COH.

- Number of Birds in a given space (bird density) is more in ECH as compared to birds kept in CO (0.8 sq.ft per bird).